Otherwise, setting up unrealistic or unachievable standards could have a demoralizing effect to employees. Standard costs are also known as “pre-set costs”, “predetermined costs” and “expected costs”. Steve is a trained content and copywriter for the industrial, electrical, and safety markets, based in the United States.

- Or the cause could be a supplier or sourcing issue in which the material can be sourced cheaper elsewhere.

- Standard cost projections are established for the variable and fixed components of manufacturing overhead.

- It sets benchmarks for financial performance by comparing actual costs to these standard costs.

- Standard Costing helps to apply the principle of “Management by exception”.

- For example, if labor costs are higher than expected, it could be due to overtime or inefficient processes.

Explore the Benefits (and Avoid Potential Pitfalls) of Standard Inventory Costing

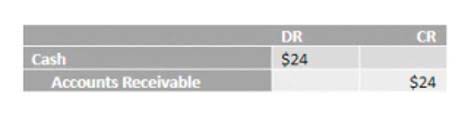

Each of these recording transactions variances are discussed in detail in the following sections. It uses actual costs for direct materials and labor but applies predetermined rates for overhead, based on measures like machine hours or direct labor hours. The use of standard costing also enhances the transparency of financial statements. By comparing actual costs to standard costs, companies can clearly identify variances and their impact on profitability. These variances are typically reported in the income statement, providing stakeholders with a detailed view of the company’s cost management performance. This level of detail is invaluable for investors, creditors, and other stakeholders who rely on accurate financial information to make informed decisions.

The benefits of standard costing

If material costs rise, it could be due to supply chain disruptions or price hikes. Keep an eye on local factors like changes in oil prices or new regulations, as these can affect your costs. Work-in-progress (WIP) control account is debited with actual costs and credited with standard costs of completed units.

What are the disadvantages of standard costing?

- The amount by which actual costs exceed the standard costs or budgeted costs.

- Direct labor involves the wages paid to workers who are directly involved in the manufacturing process.

- Quantity standards refer to the acceptable units of raw materials (direct materials) and labor hours (direct labor) used to produce a product or provide services.

- When we multiply the additional 12 yards times the standard cost of $3 per yard, the result is an unfavorable direct materials usage variance of $36.

- You might view this account as containing the cost of the products in the finished goods warehouse.

This will help to improve the efficiency and promote cost cutting within the business where applicable. Cost accounting mainly involves determining different costs of a business and classifying them using different methods. For example, it can be used to identify the variable, fixed, direct and indirect costs of a business. Once these costs are determined, cost accounting involves the use of different costing techniques to determine the costs of different products, departments or areas of the business. Another particular method that is used within cost accounting is Standard Costing. Beyond operational cost control, standard costing plays a strategic role in evaluating profitability, pricing decisions, and investment planning.

Why do manufacturers use standard costs?

Companies use standard costs for budgeting because the actual costs cannot yet be determined. This is because in the manufacturing process, it is impossible to predict the demand of a product or all the variables that will affect the costs of manufacturing it. Calculating standard costs involves a meticulous process that integrates various data points to establish a reliable cost framework.

Direct labor

Variance analysis allows management to track expenses and identify variances that may have an impact on profitability. Cost criteria should be revised on a regular basis to reflect changes in pricing, wages, and production methods. Updating these metrics ensures that they are still relevant and achievable in the current business context. Ignoring updates may result in outdated benchmarks that misguide decision-making. This is a forecast of the average prices of material during the future period. This standard is quite difficult to establish because prices are regulated more by the external factors than by the company management.

Setting for Overheads

Organizations often use a combination of these approaches to gain a comprehensive understanding of costs. While standard costing provides stability and control, actual costing reflects the dynamic nature of business operations. By carefully considering the context and purpose, managers can make informed decisions that drive efficiency and profitability. Hence, the financial statements would still reflect the actual costs incurred. Say a winery establishes standard costs for labor where each case of wine should require 0.5 hours of direct labor https://blogsgod.com/protecting-your-business-accounts-receivable-2/ at a standard rate of $20 per hour. The actual labor used was 5,200 hours at an average rate of $21 per hour.

Material Resource Planning (MRP)

Brad invented NoTuggins, a revolutionary dog harness that stops dogs from pulling when connected to a leash by humanely redistributing the dog’s pulling force. NoTuggins was featured as the most innovative new harness by the International Kennel Association. Brad sold 150,000 units of NoTuggins during the first year of operations.

- These tell you whether you’re controlling overhead costs and utilizing capacity effectively.

- It could mean that the direct materials quantity standard needs to be reduced to achieve an accurate standard variable cost per unit.

- Industry benchmarks are used to compare a company’s performance against industry standards, helping to set competitive and achievable cost targets.

- Implementing standard costing can be challenging without the right tools.

- Standard cost helps to prescribe standards and the attention of the management is drawn only when the actual performance is deviated from the prescribed standards.

- As production becomes more automated and overhead grows as a percentage of total cost, these simplified approaches become less accurate.

- For instance, minor variances might be overemphasized, leading to unnecessary corrective actions, while significant underlying issues remain unaddressed.

Video Illustration 8-1: Standard costs for manufacturing costs

If you don’t use standard costing, don’t worry — standard costing Fishbowl supports multiple costing methods, helping you track your inventory value with ease. Your budgets need a foundation built on data so you can forecast expenses and allocate resources with confidence. It’s easier to plan for the future when you know what something should cost, and that’s what standard costing offers — a budget based on real spending. Imagine you run a hotel where servicing each room means spending $20 on cleaning supplies, $10 on laundry, and $15 on the housekeeping staff’s pay. The standard cost for turning over a room for the next guest would be $45 — a benchmark that can help you see when your actual costs are higher or lower than they should be. A hotel chain establishes regular pricing for products such as room amenities, housekeeping services, and maintenance activities.